Wordwide Production Manufacturing Network

Xi'an, Xinjiang, Baoji, Algeria, Malysia, Ethiapia, Brisal, Shacman has an efficient global network of state-of-the-art production sites. It turns out that the focus on core competencies, the strengthening of future-relevant technology fields, the reduction of network complexity and efficient value creation structures are very essential.

SHACMAN XI'AN HEAD PRODUCTION INDUSTRY

SHACMAN BAOJI PRODUCTION BASE

SHACMAN ALGERIA FACTORY

SHACMAN XINJIANG MANUFACTURING PARK

Global State-of-the-Art Production Line

With a daily output of 500 heavy-duty trucks and cumulative production surpassing 2 million units, Shacman operates the world's most advanced heavy truck assembly line. From the Silk Road to the Pan-American Highway, Shacman's 900,000+ operational units across 90 countries testify to our commitment: Engineering durability that outlives roads

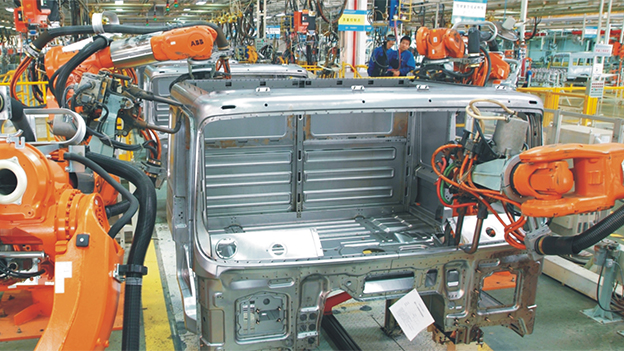

Punching and Pressing Workshop

Painting Workshop

Welding Workshop

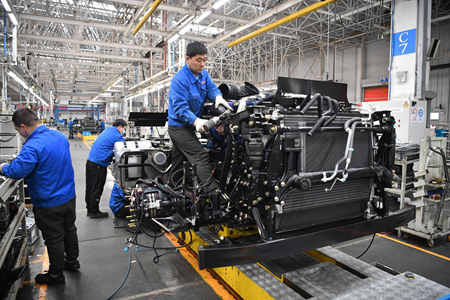

General Assembly Workshop

Certified Production Engineer | Lean Manufacturing Specialist | ISO-Certified Operational Excellence

At Shacman, we implement a rigorous production training system encompassing both engineers and frontline workers. While advanced equipment forms the backbone of manufacturing, human expertise ultimately drives operational excellence. Our quality assurance stems not merely from comprehensive systems, but equally from continuous workforce development - ensuring every team member masters cutting-edge technologies through structured competency building.

Leveraging Big Data Analytics for Cross-Process Quality Optimization in Shacman Truck Manufacturing & Operations

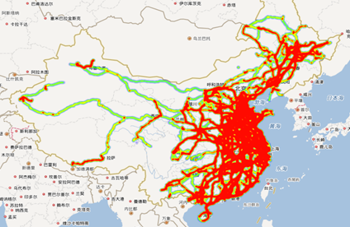

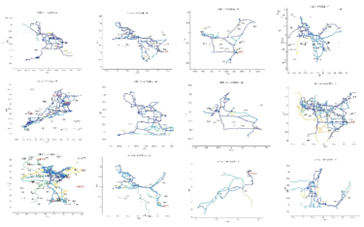

With 520,000 operational trucks generating 1.2 billion post-service data entries in the digital era, Shacman confronts the dual reality of big data's potential and complexity. By systematically tracking 75 precision-engineered quality metrics – spanning vehicle testing protocols, fuel consumption patterns, and driver behavior analytics – we have engineered an integrated quality intelligence platform. This data-driven ecosystem seamlessly connects every phase of truck lifecycle management, from R&D and manufacturing to real-world operations and predictive maintenance.

During the truck research and development, based on truck 613 developping process and quality big data platform, shacman is guided by high-end and intelligence, analyzing users optical demands and requirements, focusing on user operation pain points, driving the truck developing cycle. In this way, the truck development will be more meaningful.

Shacman build completed heavy truck supply chain together with over 400 industry partners. As the key of the supply chain, Shacman analysis the quality data, positioning the problems immediately, and optimizing it together with our supply chain from multi-dimensional sides. The optimization will be followed closely by the big data platform, in this way, we can establish the win-win comprehensive heavy duty truck supply chain and harmonious ecology.

Shacman MES system make sure the production 4 keys, man, position, time, and material, no wrong, forming the production tracking production procedure data. During the running, fuel consumption, truck track, driving behaviors and other data are continuously collected into the big data platform, making the truck production and operation visualized and trackable.