Project Background 1

Feedback from clients from different areas, that truck model from same distributors in the same production batch, they looked like quite different. Some end users called Shacman head office, and reported that they bought “fake” Shacman truck.

Same truck, watercooler in different position

Project Background 2

When first batch of 200 units L3000 model exported to Algeria in SKD, the truck was equipped with top guide cover, sized in 2265mm(width) x 957mm(height). However, the netx batch of 500 units L3000 model, the top guide cover changed in size 2424mm(width) x 846mm(height). The two sizes were in quite different. The change of top guide cover bought in 2 critical problems. Problem 1, it can not be fitted in 40HQ container. Problem 2, when we disassembled the top guide cover in CKD, the truck BOM is different with what we backed up in Algeria custom. We spent huge time and energy dealing with tough issues, although all were solved at last, it leaded to a big lesson caused by product inconsistency.

Project Background 3

There was a batch of 12 units dump trucks exported to Philippines. The 12 truck units should be in the exactly same specification. However, the truck arrived, client found that the water hanbao and pipelines are in different positions. This was quite hard to understand, why in the same model, same specification, and same batch, the Shacman truck differed so much.

Same batch, different pipeline design

Shacman Improvement Proposal

After the completed evaluation from product demand, design and production, to ensure the high consistency of the production and quality, we found that the key point is to fix the suppliers and the production SOP.

To improve the product consistency, enhance shacman truck performance, and improve the service efficiency, Shacman did hard work on the supply chain. We did comprehensive investigation and follow-up on top 500 pcs of failure rate statistics. In the late 2 years, we select the top 29 classifications of spare parts, which influence the truck performance the most. And in the 29 parts, we compared the whole supply chain, and selected the best reliable and stable supplier as our fixed partner. For some key parts, we work with imported world leading brands, such as Freighter filters, WABCO volve, WABCO drying tank, EATON clutch, VOSS connectors etc..,

In the 29 parts classifications, 22 class is common worn-out parts, and the last 7 class is critical parts. Total 879 spare part ID get involved, with 640 spare parts are individually supplied, and the remained 237 spare parts are supplied by at least 2 different suppliers.

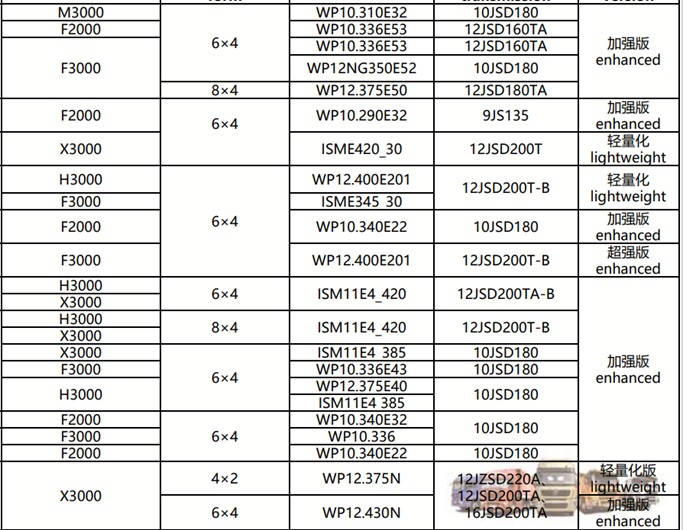

Popular models and specs for oversea market

Besides that, we do further more.

- We locked 24 popular Shacman truck models for oversea market, with all parts fixed.

- All the spare parts must follow the same procedure covering from spare part purchase, logistic transportation, incoming material quality inspection, the product in-process production, and final inspection. And all spare part must follow the completed quality inspection standard.

- Focus on the market feedback from clients, and from end users, for further improvement.

Truck quality is the key for long term corporation with clients. Truck product consistency is critical to improve the reliability, more flexible for client accessory service. We always hear the voice from clients, and keep doing better.